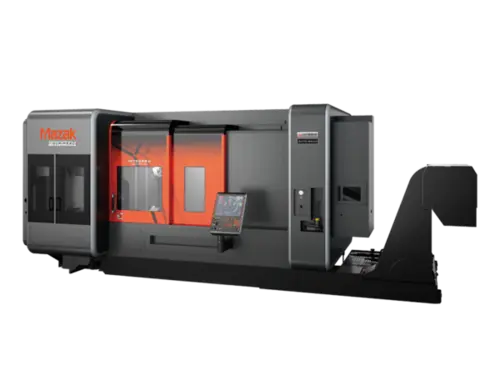

The INTEGREX i-200ST AG HYBRID Multi-Tasking machine delivers maximum versatility and throughput for medium to large complex parts. The machine combines the capabilities of a high-powered turning center and full-function machining center to produce parts in single setups, along with innovative HYBRID functionality.

This machine configuration features a second turning spindle (S) for DONE IN ONE® machining; lower turret (T), minimizing fixtures, tools, handling and non-cut time; and the HYBRID AUTO GEAR (AG) package with a full range of SMOOTH TECHNOLOGY solutions for DONE IN ONE® gear production as well.

Additionally, the machine significantly reduces lead times and improves part accuracy through the elimination of multiple setups. With full 5-axis capability, the machine easily processes fully prismatic parts from solid blocks or castings (chucked or bar fed work), round parts, or sculptured parts such as aerospace components.

We use cookies to improve your experience. Privacy Policy.